3

GLUING AND CUTTING

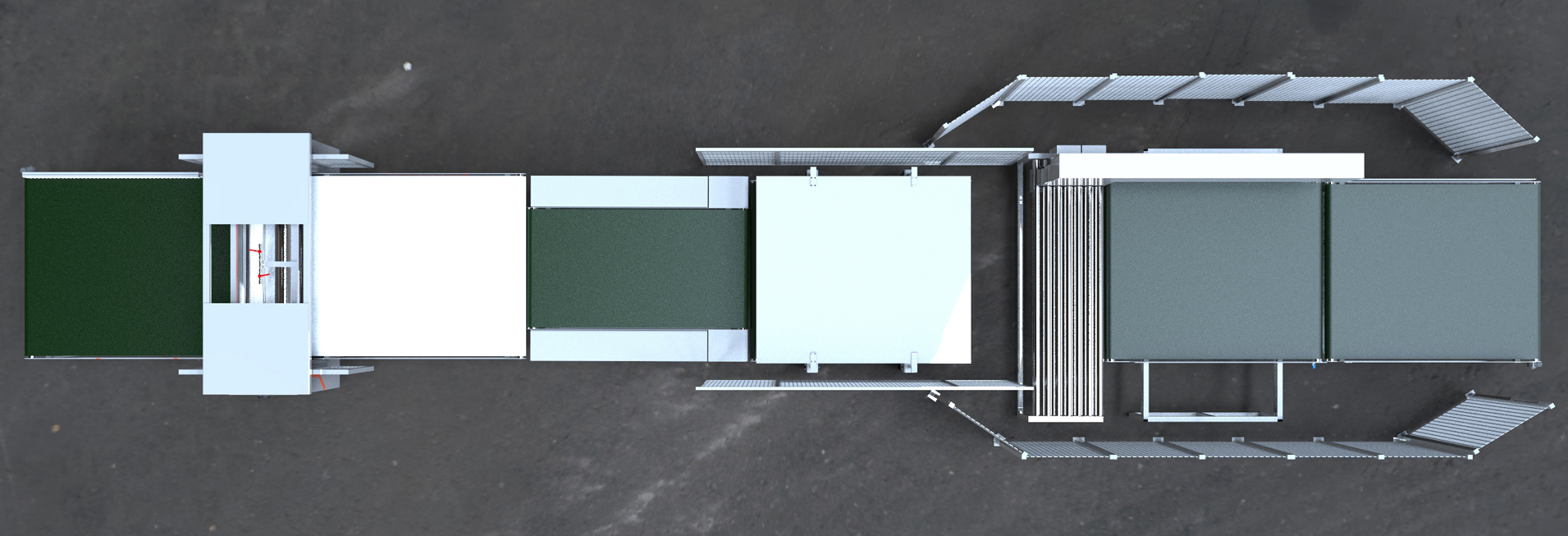

The gluing and cutting line consists of : rolling machine, assembly table , press and trimmer.

This is a solution designed to obtain the perfect product , with the correct dimensions at the end of the production process.

This solution offers the advantage of eliminating material handling therefore space and labour, avoiding the need to trim the product after the gluing process, it reduces operations on the cutting machine upstream of the production process and is able to obtain products with customised dimensions at the end of the production process.

MACHINES IN LINE: AX-R+ NTS AX-PRL AX-T

Gluing and cutting line

Gluing and cutting line: personalized and innovative solutions

Aper offers you several different production lines to best manage any activity: gluing, drying, assembling, cutting, bonding, pressing, spraying, drilling, trimming, packing, and stacking or palletizing. Aper solutions solve any problem associated with any production phase in an optimal automated way, granting countless advantages. Among these, production increase, complete process automation, glue economy of up to 50%, labor reduction, overspray elimination, quick drying, the possibility of working in line, the utmost application ease, and excellent production speed.

Aper solutions are completely automated and allow to drastically optimize the production process of foam, pocket and bonnel mattresses. Furthermore, our machines minimize wastefulness while always guaranteeing the highest quality of the finished mattress.

Always in step with a constantly-evolving market, Aper srl offers personalized solutions tailored to the individual client’s needs.

You can define with us the production line that best suits your needs, with the certainty that the system you purchase will always will always guarantee top-notch efficiency and performance.

Aper srl encourages mattress producers to work in line: this way they will be able to avoid wasting time and space and maximize labor reduction. Thanks to Aper production line, the finished mattresses can be swiftly loaded on the delivery trucks and reach the customers as soon as possible.